As a consumer, you probably don’t think a whole lot about the testing that sunscreen undergoes as it progresses from a formula to a finished product. But lately, we have heard people ask how the SPF number on a package and other claims are determined. So here are the facts on the testing that happens before a sunscreen can be sold in the US.

FDA Regulation

First, it is good to remember that sunscreen in the US is regulated by the FDA and is considered an Over-The-Counter drug. As such, the FDA produces a large document called a monograph. All the rules that sunscreens must follow are in the monograph. The FDA does not “approve” individual sunscreens for sale, it expects strict adherence to the monograph, which will result in a product that is effective, has undergone all required testing and contains only approved active ingredients. Products that do not follow the monograph should not be considered safe to use, and you don’t want to trust the SPF listed on the label, as it may not have undergone proper testing. The quickest way to determine if a product is FDA compliant is to look at the Drug Facts panel. If there isn’t one, the product is not FDA compliant and should be avoided.

SPF Testing

A sunscreen’s SPF value refers to the level of protection it provides against UVB rays, the rays which are responsible for sunburns and many skin cancers. In the formulating process, the chemist and brand determine what SPF value they hope to reach. When they have a formula they like, they can submit it to a testing laboratory for a two-person panel, which will give them an indication that the formula is on the right track. This testing is done on individuals who are paid volunteers, which is one of the things that makes sunscreen testing expensive. If the formula meets the target SPF on two subjects, then the brand will move ahead to full SPF testing on ten subjects. If it does not test out to the target with two subjects, it’s back to the formula drawing board, then the testing happens again. Once the formula passes the full 10-subject panel, the brand is provided with the final results which include the maximum SPF that can be claimed by that product/formula.

Water Resistance Testing

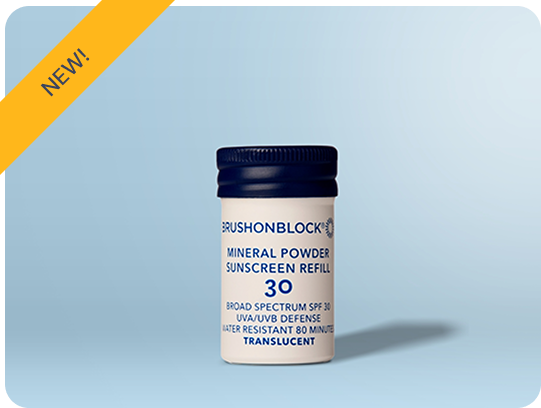

No sunscreen is truly waterproof, but brands used to be able to claim that they were. In 2011, the FDA decided that this claim was misleading, and now sunscreens are only allowed to claim to be water resistant for either 40 minutes or 80 minutes (or not at all). If your sunscreen does not say water resistant for one of these lengths of time, if may only mean that the product has not been tested, but it also means that you should not rely on it while swimming or sweating.

When it comes to the water-resistant claims, the brand must determine which level of water resistance they want to claim, and then undergo testing for that. The test involves the subjects (again, people) wearing the sunscreen, then sitting in a hot tub or jacuzzi, getting out and allowing the skin to air dry, then having it tested to see if it still provides the SPF on the label. The subject will submerge the sunscreen and test several times during the testing period. If at any point, the sunscreen does not provide the testing on the label, the product fails that water resistance test.

Broad Spectrum Testing

Broad Spectrum refers to a sunscreen’s ability to provide protection from both UVA rays (the ones that contribute to premature skin aging and some skin cancers) and UVB rays (those rays that cause sunburn). FDA requires that the UVA protection is proportional to the UVB protection and as the SPF level goes up, the level of UVA protection must go up as well. The broad spectrum testing requirements are outlined in the FDA sunscreen monograph and if a sunscreen passes this test, it can be labeled “broad spectrum” on the front panel.

RIPT Testing

RIPT stands for Repeat Insult Patch Testing. Passing the RIPT test means that a product can claim to be Hypo-allergenic or non-irritating. It is done over a period of six weeks to see if any of the subjects develop any sort of reaction to the formula. If a product passes this test, it can claim to be hypo-allergenic or non-irritating.

Microbiology testing

Every batch of sunscreen manufactured must undergo microbiology testing to make sure that there are no yeasts, molds, bacterias or pathogens present.

Assay

When a sunscreen has been assigned an SPF value, every batch of that formula that is manufactured must undergo testing along the way to make sure that the level of active ingredients is as advertised on the packaging, so that the product will provide the SPF value on the label. When a bulk batch of sunscreen is made, samples are drawn and tested to be sure that the level of active ingredients is consistent. Then, once the product is being packaged, again samples are pulled and tested for active levels. This is your assurance that there is never a “bad batch” of sunscreen and that the batches have been properly mixed so that the actives are equally dispersed throughout the formula for your safety and protection.

Stability Testing

And finally, there is Stability Testing, which determines how long after manufacture the product is “good” before it expires. This testing happens with every batch at the beginning of a formula’s life, and with at least one batch per year after that. In Stability testing, samples are kept in temperature-controlled chambers and checked at regular intervals to determine if the product looks and smells as it did when it was manufactured, and that the active ingredients have not degraded. If it passes these checks, it is good to move ahead to the next interval of testing. Once a product has been in real-time stability testing for three years and has shown no change in look, scent or effectiveness, the FDA allows that product to be sold without an expiration date. However, they do recommend that if you purchase a sunscreen that has no expiration date, you should use it up within three years of the first time it is opened.

Brush On Block has passed the three-year testing threshold on most of our products, but you will notice we often still print an expiration date because some areas in which we sell require it.

Use As Directed

This run-down of testing should dispel any concerns that sunscreens are not able to live up to the numbers on their labels. As with any drug-product, it is critically important that you use it as directed. With sunscreen, that means apply enough in the first place, reapply at least every 2 hours, reapply if swimming or sweating according to the time on the label, reapply if you wipe your skin off with a towel or sleeve and use additional sun protection measures during peak sun hours of 10 am to 2 pm.